In October 2024, Zhengzhou Shuanglian Building Material Co., Ltd. successfully exported one ton of cured floor coatings to the Philippines, injecting new impetus into the industrial and commercial flooring market in the region. The exported products are specifically designed for high-strength and high-wear-resistant floor construction needs, and adopt environmentally friendly and efficient cured floor coating solutions. This marks that Zhengzhou Shuanglian's competitiveness and influence in the international market have been further enhanced, further expanding the coverage of the Southeast Asian market.

What is concrete curing floor?

Solidified flooring is to use cement floor hardener to penetrate into the concrete, react chemically with the components in the concrete to form hard crystalline substances, thereby greatly improving the strength, hardness and wear resistance of the concrete floor, effectively solving the problems of cement floor dust and sand. After grinding and polishing with professional construction machinery, it will have a marble-like luster. Once you own it, you will enjoy it for life.

Construction process

1、Construction tools

Floor grinder, vacuum cleaner, multifunctional floor scrubber, rain boots, wiper, mop, broom, dust pusher, watering can, pipe, bucket, portable polisher, diamond resin grinding disc (50 mesh, 150 mesh, 300 mesh, 500 mesh, 1000 mesh, 2000 mesh, 3000 mesh) diamond grinding disc (16, 30, 80, 120).

2、Base treatment

Before construction, remove loose ground and dust, debris, etc. If there are broken ground or potholes, use repair mortar to repair and fill.

3、Rough ground

Grind with 50 mesh resin grinding disc, keep the speed uniform and cross-grind (water grinding or dry grinding), then clean it and grind with 150 resin grinding disc. Until all the rough scratches left by 50 mesh grinding are eliminated and cleaned. (For rough and uneven floors, it is recommended to use a metal grinding block to grind the floor, and then use a resin grinding disc to grind it after grinding).

4、Apply curing agent:

After grinding with 150 mesh, dilute the curing agent with water in a 1:1 ratio, and spray it evenly on the floor with a watering can. Keep the floor moist for 20 minutes. If there are dry areas, use a wiper to scrape them over to ensure that the floor is completely and evenly penetrated. After the first coat is sprayed, let the floor dry until there is no obvious moisture, and then apply the second coat according to the above method.

5、Fine grinding of the floor:

After the curing agent is dry, use a 300 mesh resin grinding disc to grind the floor that has been penetrated (water grinding or dry grinding), and grind evenly to remove the residual material on the floor. After grinding, clean it at the same time, and then grind it again with 500 mesh.

6、Fine grinding and polishing

Use a 1000 mesh resin grinding disc to dry grind directly on the ground. At this time, the speed of the machine should be controlled as uniform as possible, so that the ground can appear shiny. If a higher gloss is required, use a 2000 mesh or 3000 mesh grinding disc to polish according to the above method to increase the gloss.

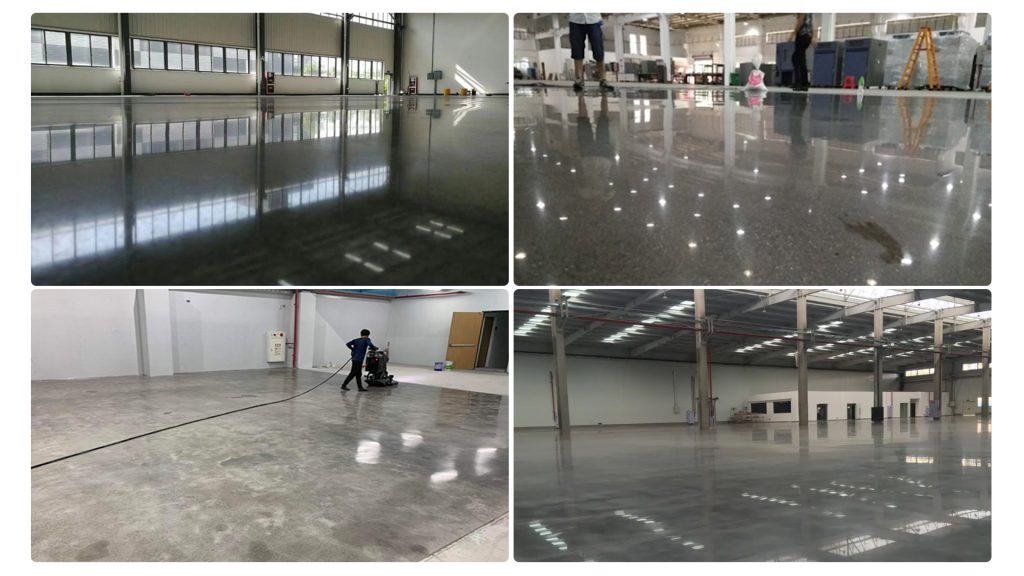

The following is the construction effect diagram