Epoxy flooring has high strength, wear resistance, no joints, solid texture, waterproof, anti-corrosion and dustproof. It is not only convenient to construct and maintain, but also low in price, and is suitable for various venues.

Technical characteristics of epoxy flooring:

1.High strength and wear resistance: Epoxy floor paint has high hardness and wear resistance, and is suitable for floors with high intensity use in industrial environments.

2.Chemical resistance: It can resist the erosion of various chemicals, such as acids, alkalis, solvents, etc.

3.Dustproof and easy to clean: The paint film has a smooth surface, good dustproof effect, and is easy to clean and maintain.

4.Good adhesion: It can adhere well to the surface of substrates such as concrete and cement, and is not easy to peel off.

5.Beautiful: It has a variety of colors to choose from, and can provide glossy or matte decorative effects.

Construction process of epoxy flooring

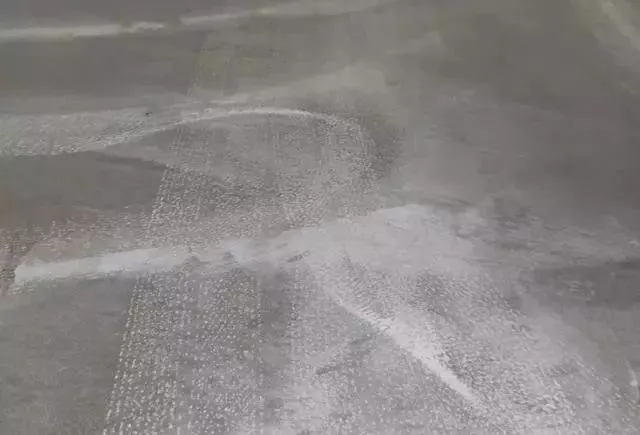

Base treatment

Make sure the surface of the substrate is clean, dry, oil-free, and free of loose substances. Grind or sandblast if necessary.

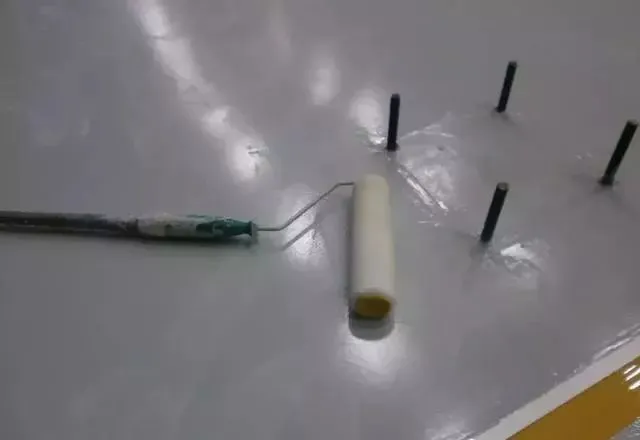

Primer construction

Apply one coat of primer to enhance the adhesion of the ground and the paint film. The amount is area x 0.2 kg.

Intermediate coating construction

Apply the intermediate coating after the primer is completely dry. Add appropriate amount of quartz sand as needed. To increase thickness and flatness. The amount of one coat is area x 0.35.

Topcoat construction

Apply epoxy topcoat after the intermediate coating is dry to form the final protection and decorative layer. The amount of two coats is area x 0.4.

Use and maintenance of epoxy floor

- After the coating is applied, do not use it during the maintenance period, and strengthen ventilation equipment and fire prevention measures.

- When using the floor, production personnel are not allowed to walk on it wearing leather shoes with iron nails.

- All work tools must be placed on a fixed special frame. It is strictly forbidden for metal parts with sharp angles to collide with the ground, causing damage to the floor coating.

- When heavy objects such as equipment are installed in the workshop and lifting machinery is required, thick rubber or other soft materials should be placed at the supporting points that contact the ground. It is strictly forbidden to use iron pipes or other metals to connect and drag equipment on the ground.

- Once the floor is damaged, use paint to repair it in time to prevent oil from penetrating into the cement through the damaged area, causing large-scale paint to fall off.