Epoxy floor coating is a high-performance coating composed of epoxy resin and curing agent, which is widely used for ground protection in industrial and commercial places. It is characterized by high strength, strong wear resistance, and can withstand corrosion from a variety of chemicals. It is usually used in factory workshops, parking lots, hospitals, etc., and can form a smooth, strong and easy-to-clean floor.

1、Basic composition of epoxy floor paint

Epoxy floor paint is a two-component coating, mainly composed of epoxy resin and curing agent. Epoxy resin is a viscous liquid material with strong adhesion and chemical stability; while curing agent is a chemical substance that can promote the hardening of epoxy resin. After the two are mixed, a hard solid film layer is formed through chemical reaction. Usually, epoxy floor paint will also add some auxiliary materials, such as pigments, fillers, toughening agents, etc., to improve its performance and decorative effect.

2、Advantages and disadvantages of epoxy floor paint

Advantages

- High strength and wear resistance: The coating of epoxy floor paint has high hardness and excellent wear resistance, which is suitable for heavy-duty places such as factory workshops and warehouses.

- Resistant to chemical corrosion: Epoxy resin has good resistance to chemicals such as acids, alkalis and solvents, making it suitable for environments such as chemical plants and laboratories.

- Waterproof and dustproof: The epoxy coating forms a dense seamless film, which can effectively prevent the penetration of moisture and dust, keeping the floor clean and tidy.

- Aesthetics: Epoxy floor paint has a variety of color options, and can customize the appearance of the floor according to actual needs, which is suitable for decoration in commercial and home environments.

- Easy to clean and maintain: The surface of epoxy floor is smooth, easy to clean and maintain, and not easy to hide dirt, especially suitable for environments that require high cleanliness.

Disadvantages

- High construction requirements: The construction process of epoxy floor paint is relatively complicated, and the treatment of the ground foundation is very important. Any impurities or moisture may cause problems with the coating.

- Long construction time: Due to its multi-layer construction process, epoxy floor paint requires a long curing time, especially in low temperature or high humidity environments, it may take several days to dry.

- Not UV-resistant: Epoxy floor paint is prone to yellowing due to ultraviolet radiation when used outdoors, so it needs to be protected when used in outdoor environments.

- May produce volatile organic compounds (VOC): Although most modern epoxy floor paints have improved their environmental performance, a small amount of VOC may still be released during construction, and attention should be paid to ventilation.

3、Construction technology of epoxy floor paint

The construction process of epoxy floor paint determines its final performance and appearance. The construction is usually divided into three main steps: ground preparation, primer, midcoat and topcoat.

Floor preparation

- Before construction, the floor must be thoroughly cleaned and trimmed. Any cracks, holes or bumps must be repaired, and the floor must be completely dry to ensure full bonding between the epoxy resin and the floor. If the floor is wet, the coating may bubble or fall off. In addition, use a grinder to grind the floor to ensure surface roughness to enhance adhesion.

Primer

- The main function of the primer is to enhance the adhesion of the epoxy floor paint to the floor. The primer is usually a transparent or light-colored epoxy resin, which is evenly applied to the floor by rolling or spraying. The primer penetrates into the fine pores of the floor and acts as a seal, providing a solid foundation for subsequent coatings.

Middle coating

- The middle coating is to increase the thickness and strength of the floor. During construction, fillers such as quartz sand are usually added to the epoxy resin to enhance the compression and wear resistance of the floor. After the middle coating, grinding is required to ensure that the surface is flat and free of particles.

Topcoat

- Topcoat is the last and most critical step in the construction of epoxy floor paint. Topcoat can provide the final gloss, color and chemical resistance to the floor. Epoxy topcoat can be smooth, matte or non-slip, depending on the application scenario.

4、Common application scenarios of epoxy floor paint

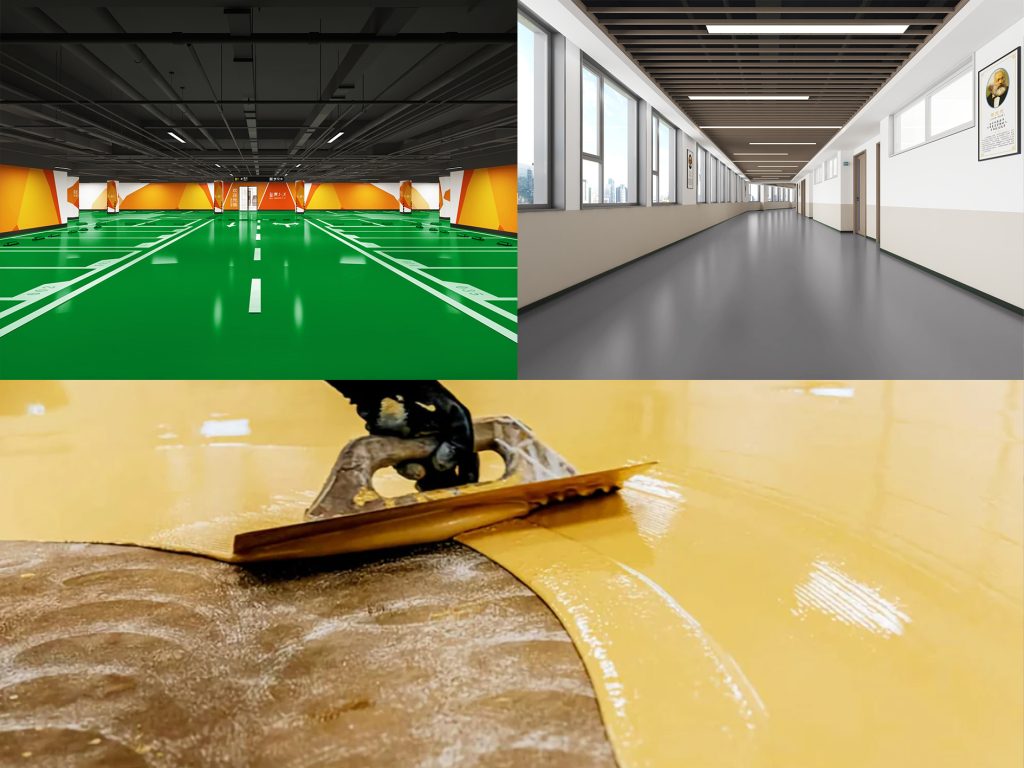

Epoxy floor paint is widely used in many fields due to its superior performance. Here are some common application scenarios: industrial sites, commercial and public buildings, home garages and underground parking lots, pharmaceutical and food industries.

Epoxy floor paint is very suitable for heavy industrial sites such as factory workshops, warehouses, machinery and equipment rooms, etc. Its wear resistance, dust resistance, and pressure resistance can cope well with high-frequency heavy equipment operations. In places such as shopping malls, hospitals, and schools, epoxy floor paint can provide beautiful and easy-to-clean floor effects, while also having anti-slip functions to ensure pedestrian safety. Epoxy floor paint is very popular in home garages and underground parking lots. Its anti-slip, anti-oil and easy-to-clean characteristics make it an ideal choice for car owners. In addition, the chemical resistance of floor paint can also effectively prevent the erosion of automotive oils. In environments with high requirements for hygiene conditions such as pharmaceutical factories and food factories, the seamless and dust-proof characteristics of epoxy floor paint are particularly important. Its antibacterial coating can reduce bacterial growth and ensure the hygiene and safety of the production environment.

Epoxy Floor Coating is a high-performance floor coating that is widely used in industrial, commercial and household fields. Its high strength, wear resistance, corrosion resistance and easy cleaning make it an ideal choice in floor systems. If you need floor coating solutions, please contact us.