product

Two-component epoxy floor paint is a high-performance paint widely used for floor protection and decoration. It consists of two main components: epoxy resin and curing agent. When used, these two components need to be mixed in a certain proportion in order to chemically react to form a solid coating. Two-component epoxy floor paint includes primer, midcoat and topcoat. The topcoat can be painted with varnish as needed. The primer, midcoat and topcoat all have two components, AB. The mixing ratio of the two components is A:B=4:1

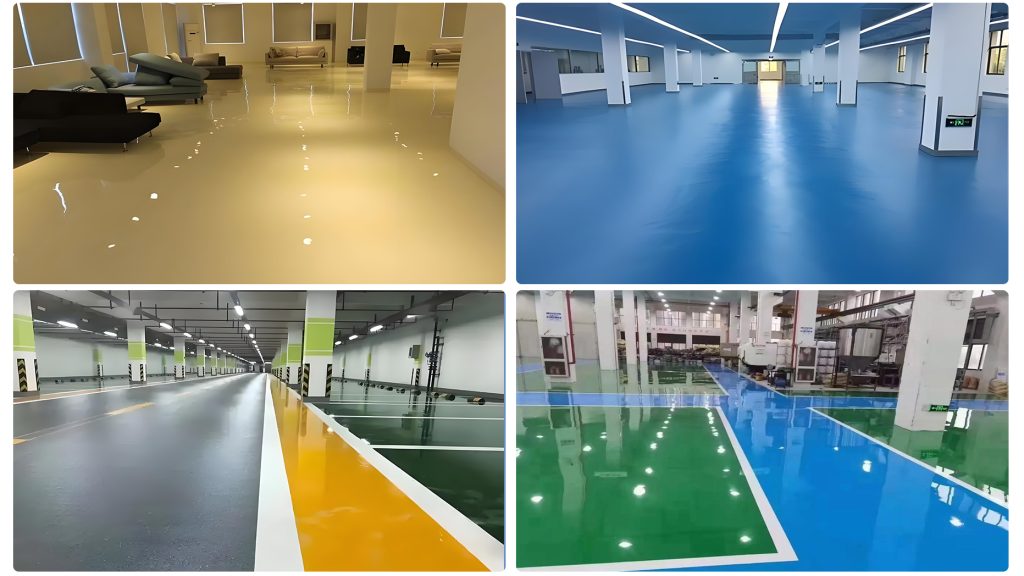

Multiple schemes can be designed according to different usage requirements, such as thin-layer coating, 1-5mm thick self leveling ground, anti slip and wear-resistant coating, mortar type coating, anti-static, anti-corrosion coating, etc. Epoxy floor paint suitable for various venues, such as factories, computer rooms, warehouses, laboratories, hospitals, operating rooms, workshops, etc.

| Test items | Value | |

| Paint film appearance | Flat and smooth Surface, No shrinkage holes, floating colors, wrinkles, pinholes, cracks, etc. | |

| Drying time (h) | Surface dry | ≤4 |

| Dry thoroughly | ≤24 | |

| Fineess,um | ≤40 | |

| Pencil Hardness | 4H (standard ≥3H) | |

| Wear resistance, g/750g/500r | 0.028 (standard ≤0.030) | |

| Water resistance (room temperature), 200h | Uniformity | |

| Anti-slip performance (Dry friction coefficient) | 0.63 (standard ≥0.5) | |

| Tensile bond strength (Mpa) | 4.8 Mpa (standard ≥2.0) | |

| chemicalresistance | Alkali resistance (20% NaOH, 72h) | No bubbling, no peeling, no discoloration |

| Acid resistance (10% H ₂ SO₄ , 48h) | No bubbling, no peeling, no discoloration | |

| Oil resistance (120# solvent oil, 72h) | No bubbling, no peeling, no discoloration | |

| Storage stability, 50℃/168h | After mixing evenly, no lumps. | |

| Methanal (mg/kg) | 40 (standard ≤50) | |