product

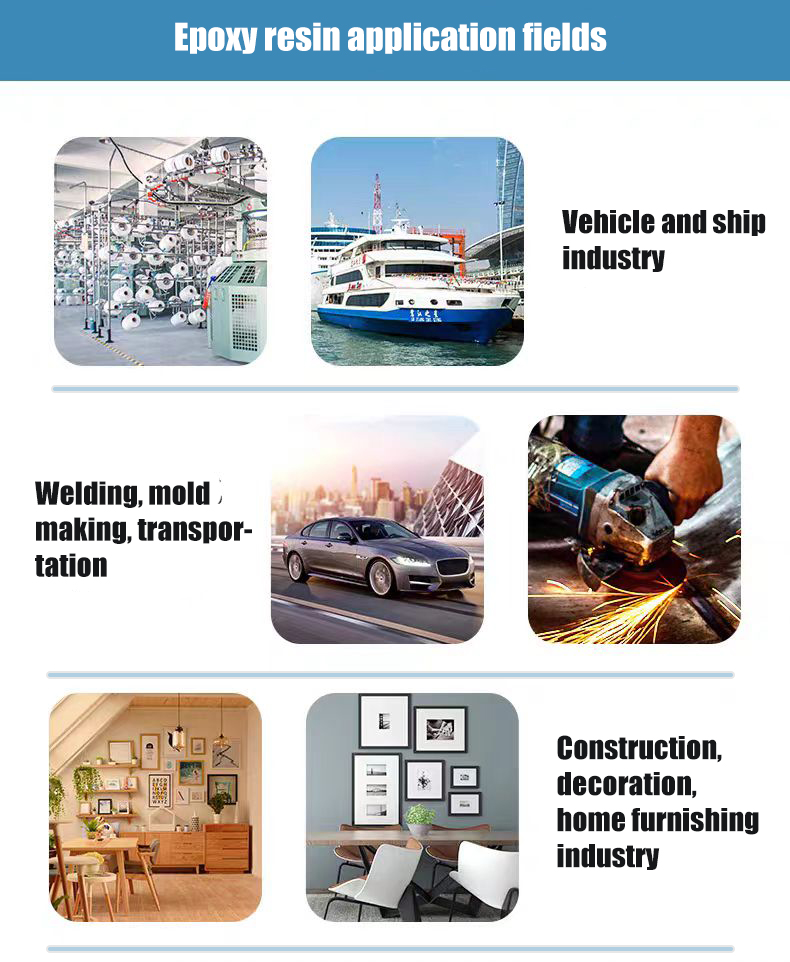

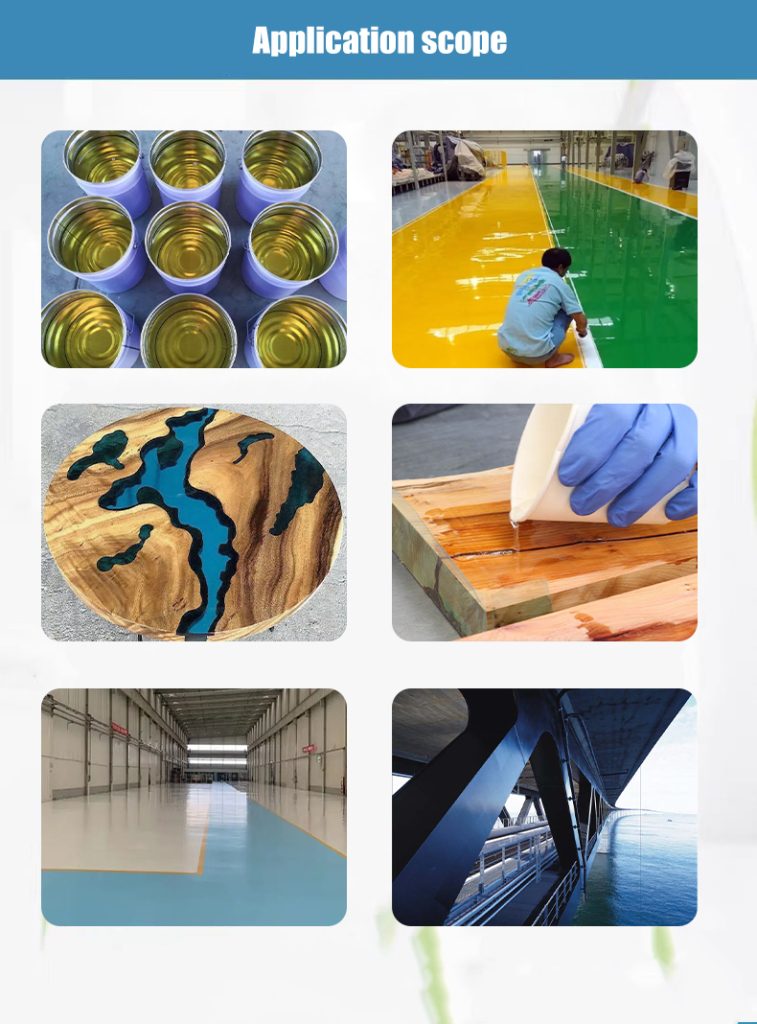

Epoxy resin is a high-performance epoxy resin with a wide range of applications and excellent physical and chemical properties. With its excellent adhesion, mechanical strength and chemical corrosion resistance, it has become an ideal material for many fields such as industrial manufacturing, construction engineering, electronic and electrical, and shipbuilding. Epoxy resin uses advanced production technology and high-quality raw materials to ensure the stability and reliability of the product, while meeting environmental standards and reducing the impact on the environment.

Epoxy resin has become an indispensable material in various industries due to its excellent performance and wide range of applications. Whether it is industrial production or daily maintenance, 128 resin can provide you with a reliable solution. I hope these detailed information can help you better understand and use 128 resin. If you have any other questions or need more information, please feel free to contact us.

| Item | Technical Parameters |

| Appearance | Colorless transparent liquid |

| Solid content | ≥99% |

| Viscosity (25℃) | 1000-1500 cps |

| Density (25℃) | 1.15-1.20 g/cm³ |

| Curing time | Surface drying takes 2-4 hours, and complete drying takes 24 hours (25°C, relative humidity 50%) |

| Tensile strength | ≥70 MPa |

| Flexural strength | ≥110 MPa |

| Impact strength | ≥10 KJ/m² |

| Heat deformation temperature | ≥80℃ |